After a project lasting two years, ENSI now has a calculation method that operates independently of the container manufacturers or owners for determining the safety margin for heat dissipated from transport and storage containers. The new method will also enable ENSI to calculate any deviations more quickly during ongoing manufacture of the containers.

The project started out at the University of Bayreuth in early April 2014 based on computer-controlled (digital) analyses that break components down into sub-elements, so-called finite elements. The faculty also developed its own software solution.

The new independent calculation method is particularly important because nuclear plant operators are keen to utilise the maximum possible heat capacity of the containers and over 40 containers of different designs are already in interim storage. New container models are developed each year.

Follow-up project underway

ENSI is keen to continue research into the design and construction of transport containers for dangerous goods and has launched a follow-up project, which commenced on 1 January 2017. This research project focuses on optimum positioning of the fuel basket in the leaktight containment, especially when the container is in the horizontal position during transport.

Extensive reporting on ENSI research projects

In addition to this project culminating in the method for calculating heat dissipation safety margins, the recently published 2016 Research and Experience Report also describes all ENSI’s other research projects.

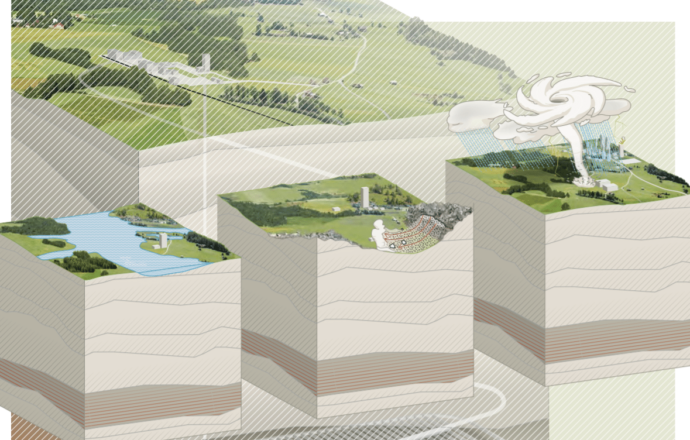

ENSI’s research strategy is based on the following key topics: long-term operation of existing nuclear power plants, ensuring protection from natural events and construction of deep geological repositories.