The nuclear fuel is extracted from uranium ore, which is enriched in one of the additional manufacturing processes.

Nuclear fuel is trapped in pellets

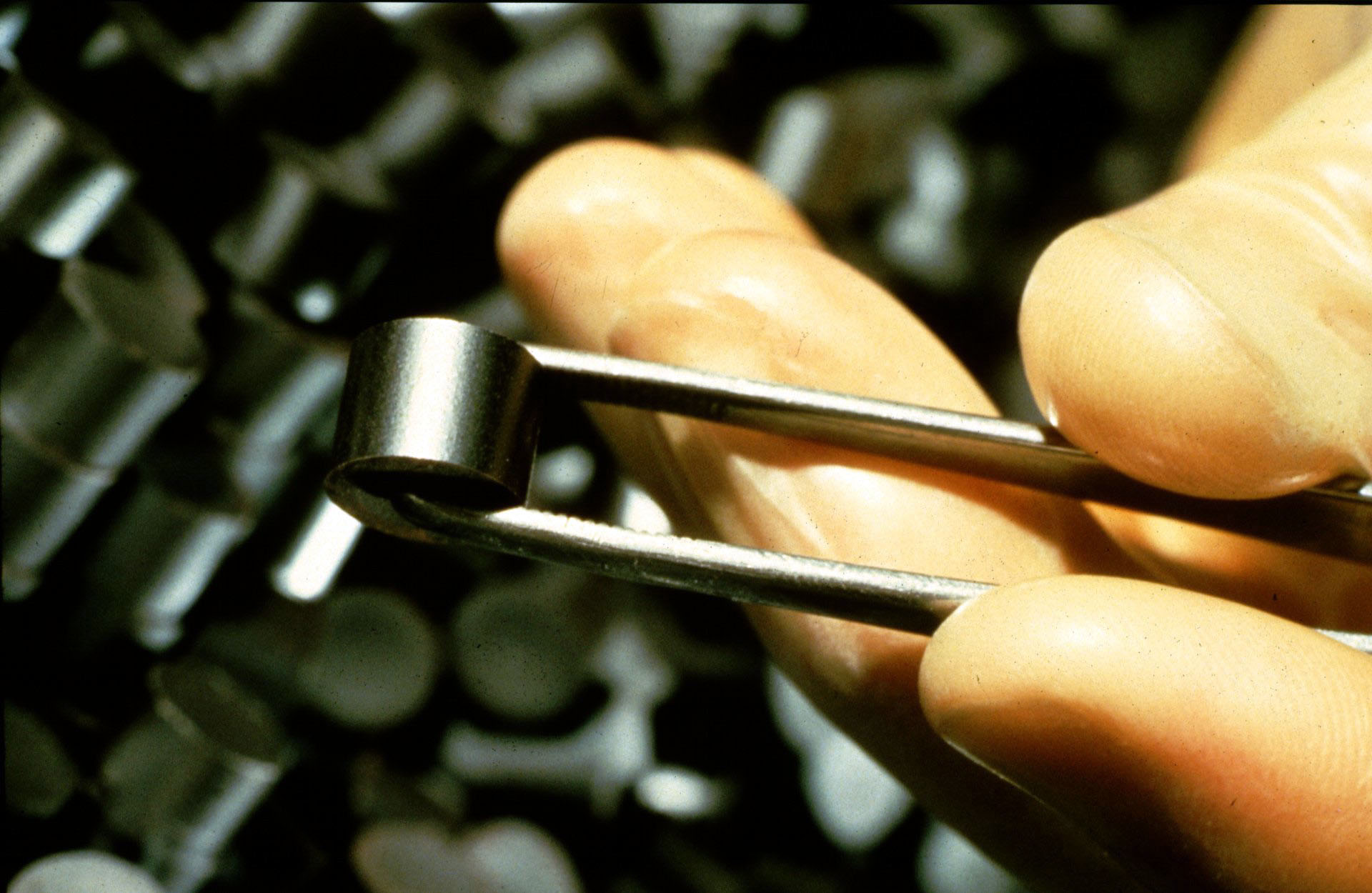

The enriched uranium oxide is ground, pressed into pellets and compacted by sintering at about 1,700 degrees Celsius, i.e. it is converted to ceramic material. This ceramic material is able to retain the fission products that arise during operation in the nuclear fuel matrix. The shape of these pellets is reminiscent of small black tablets; they are cylindrical and about one centimetre high and one centimetre wide. Pellets are only very weakly radioactive in their unused state; they only become highly radioactive in the reactor operation as a result of neutron bombardment and the resulting fission products.

The solid radioactive substances (and part of the radioactive noble gases) are trapped in a matrix in the pellets during the normal operation of the reactor. Together with the fuel rod cladding tubes, the nuclear fuel matrix is the first barrier for trapping radioactive substances.

This is the second of six articles on the topic of barriers for trapping radioactive substances. The first describes the barrier principle, while articles 2 to 6 describe the various barriers.