ENSI has accepted the back-fitting measures for the cooling water intakes at the Mühleberg nuclear power plant (KKM) and has issued a permit for them to operate. This means that the reservation imposed by ENSI at the start of September regarding proof of KKM’s ability to bring a flood under control has now been lifted. At the same time, one of ENSI’s conditions for restarting the plant after the inspection shutdown has been met.

New water intakes in the Aare

Together with the technical authorities of the Canton of Bern, ENSI accepted the new structures at the KKM to upgrade the intake structure for the SUSAN emergency system on 21 September 2011.

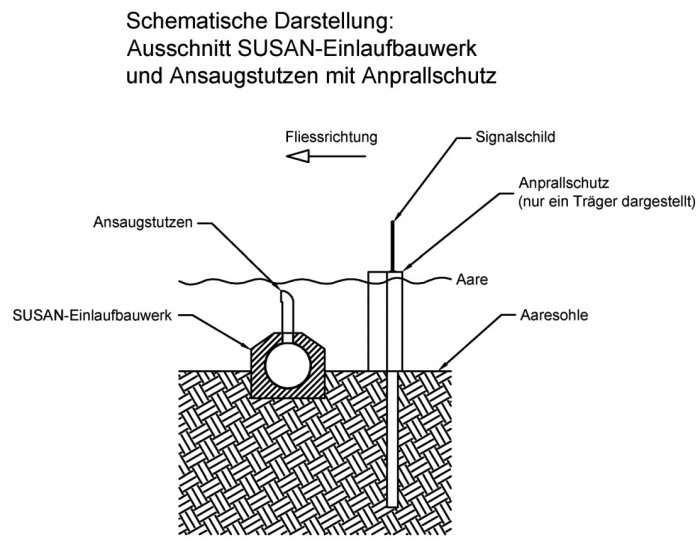

On 8 August 2011, KKM applied for a permit in respect of the construction of three new suction intakes and the associated impact protection piles in the river Aare. This measure aims to guarantee the supply of cooling water to the SUSAN special emergency system even if the main and auxiliary cooling water systems should fail due to an extreme flood, and if the Aare clogs the existing water intake with bedload and sludge.

After consulting the technical authorities of the Canton of Bern and the Federal Office for the Environment (FOEN), ENSI issued the construction permit for the planned improvement measures on 22 August.

In order to carry out the building work, BKW (the operator of KKM) used a floating construction platform with a heavy drilling machine to anchor the protection piles in the subsoil at Rewag, downstream of the power plant near the confluence of the rivers Aare and Saane.

After the platform was moved to the construction site, the first task was to drill the bore holes for the protection piles. The six protection piles were then set in place and the bore holes were filled with injection mortar. This stage was followed by the drilling of core bores in the concrete of the existing intake structure, and the installation of the new suction intakes. The construction work was carried out underwater by divers.

Second opinion: In addition to its own building inspections, ENSI commissioned its external test engineer to review the quality assurance for the construction work, and to verify that the specified requirements had been correctly implemented.

Conclusions: The construction work is in compliance with the documentation for the implementation project and it takes account of the imposed conditions. ENSI issued a permit for the operation of the structures on 22 September.

The floating construction platform is currently being dismantled. The Rewag installation site will be restored by 1 October.

Feed line in the SUSAN intake structure

On 22 September, ENSI issued a permit to operate the new feed line for the supply of cooling water to the SUSAN special emergency system. ENSI had issued a permit for the construction work on the new feed line on 19 August, in response to an application from BKW. Thanks to this feed line, which is positioned in the direction of flow behind the SUSAN screens, the SUSAN special emergency system should be supplied with cooling water from mobile pumps if the screen were to become totally blocked by organic substances. In principle, a water supply of this sort is also possible via existing equipment in the intake structure − but in case of an extreme flood, the accessibility of these covers is not guaranteed in all cases.

ENSI provided follow-through for the construction work and issued its acceptance during an on-site tour of inspection on 21 September.

Conclusions: The building work was executed in compliance with the documentation for the construction project, taking account of the imposed conditions. ENSI therefore issued a permit for the new feed line to operate on 22 September.

Mobile flood protection walls for the pump house and the buildings in the controlled zone

In order to provide protection against extreme flooding, KKM has installed mobile flood protection walls for the pump house as well as all building entrances and openings in the controlled zone. These measures were reported to ENSI. They do not require permits.

Thanks to the new mobile flood protection walls, the KKM’s pump house now has flood protection in excess of the statutory minimum requirements.

During an inspection, ENSI ascertained that the newly installed mobile flood protection walls are watertight, and that they can be erected within an adequate period. The work has now been completed and the flood protection walls are ready to operate. More information: